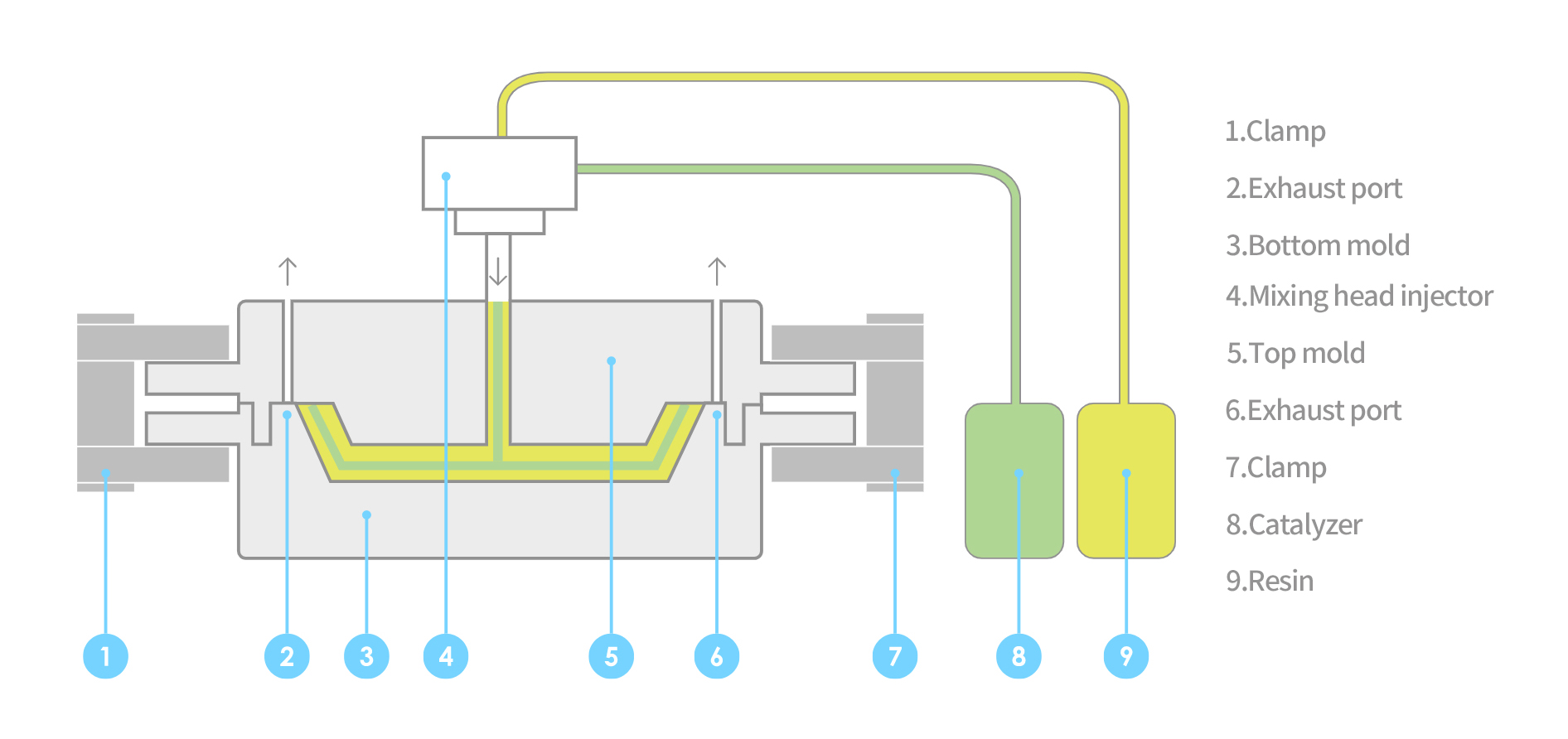

Resin transfer molding (RTM)

BFG International China uses a variety of methods to produce FRP parts. Our experienced engineers will select the best process method for your project based on factors such as production volume, parts dimensions, budget, and other requirements.

The process is best suited for high precision parts where a two-sided finish is required, and for moderate production quantities, ranging from 100 to 7,000 parts per year.

Advantages

— Suitable for mass production processes

— Works with a range of fibre reinforcements

— High surface quality on both sides

— Low environmental impact

— Less material wastage

— Capable of producing large, complex structures and hollow shapes

— Supports inserts and reinforcements for greater strength

— Zero air retention

— Laminate thickness-0.5mm to 90mm

Limitations

— The process is generally limited to smaller components

— Not suitable for parts with negative draft

— Part thickness is fixed at the time of mould construction

— Glass-resin ratios of less than 35%

Applications

We use RTM processes to create a range of high quality components including:

— Industrial furniture

— Boat hulls

— Wind turbine components

— Aerospace, rail and automotive parts

— Medical Composites